Operational efficiency in a boutique is measured by how quickly and accurately an order moves from the measurement stage to the final delivery. A tailoring app improves this efficiency by replacing verbal instructions and paper chits with digital "Production Insights." By using a dedicated tailoring application, boutique owners can monitor real-time progress, identify which department is slowing down the workflow, and ensure that every garment meets the promised delivery date.

Tracking the Journey: Monitoring Production Stages from Stitching to Finishing

In a traditional tailoring unit, the only way to know the status of a blouse or suit is to physically walk to the workshop and ask the tailor. This manual process is time-consuming and prone to misinformation. A tailoring app digitizes this journey by breaking down the lifecycle of a garment into visible stages. To ensure complete control, GrowStitch allows owners to create multiple staff logins to track work progress and enables the centralized management of multiple boutique locations from a single dashboard.

The production journey typically includes:

Procurement: Tracking when the fabric and accessories (like lining or borders) are ready.

Cutting: Marking the start of the physical creation.

Stitching: The core assembly of the garment.

Hemming & Finishing: The final touches that define quality.

Quality Check: Ensuring the garment matches the measurements.

Beyond tracking, the app allows owners and customers to add or modify adjustments, measurements, and add-ons (like extra sleeves, design changes, or fit corrections) at any stage without restarting the process or relying on verbal instructions. By having these stages visible on a mobile dashboard, the boutique owner gains clarity and control without interrupting workers. Each update is time-stamped, creating a transparent audit trail of the garment's journey and every change made along the way.

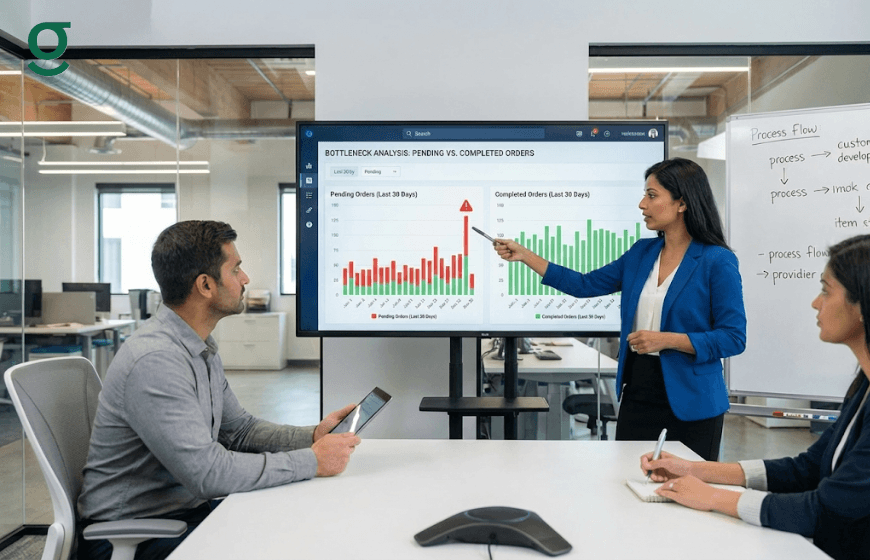

Identifying Bottlenecks: Analyzing Pending vs. Completed Orders

A bottleneck occurs when one stage of production is consistently slower than the rest, causing a pile-up of "Pending" orders. Using a tailoring app, owners can view "Production Insights" to see a numerical breakdown of orders at each stage.

For example, if the dashboard shows 50 orders in "Stitching" but only 5 in "Finishing," it is a clear indicator that the finishing team is overwhelmed or understaffed. Identifying these gaps allows owners to:

- Reallocate Resources: Move staff to the finishing department temporarily to clear the backlog.

- Adjust Timelines: Inform customers of potential delays before they become complaints.

- Manage Load: Pause new "Express Delivery" orders until the bottleneck is cleared.

Workflow Customization: Tailoring Production Steps to Your Boutique's Style

No two boutiques operate exactly the same way. A high-end bridal studio may require ten different quality check stages, while a simple alteration shop might only need three. The GrowStitch platform allows for "Workflow Customization" during the onboarding process.

Owners can customize, skip, or reorder production stages to fit their specific "Standard Operating Procedure" (SOP). If your boutique specializes in heavy embroidery, you can add a specific "Embroidery" stage between cutting and stitching. This ensures the tailoring app reflects the real-world movement of your products rather than forcing you into a generic template.

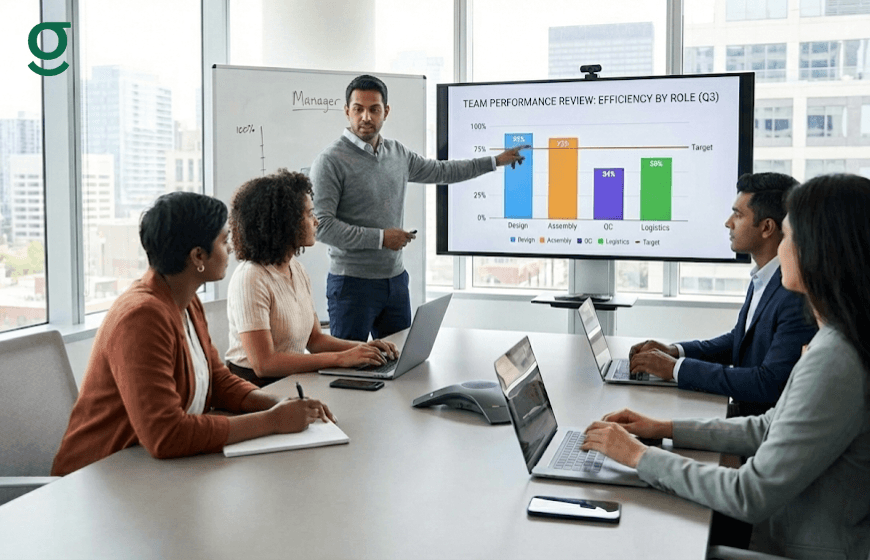

Team Performance Review: Evaluating Efficiency Across Different Production Roles

Operational efficiency is deeply tied to team performance. A tailoring app allows owners to assign specific production stages to individual team members or departments. This data-driven approach moves away from "blame games" and toward objective evaluation.

By reviewing the "Manage Teams" section, an owner can see:

- Task Completion Rate: Who is meeting their daily stitching targets?

- Accuracy: Are certain tailors seeing more "rework" or "alteration" requests?

- Consistency: Is the team maintaining the same speed during festive rushes as they do during off-peak weeks?

This oversight helps in identifying top performers who deserve recognition and team members who may need further training in specific tailoring techniques.

Quality Control and Timelines: Ensuring On-Time Delivery through Digital Oversight

On-time delivery is the primary factor in customer retention for Indian boutiques. A tailoring app acts as an early warning system. By setting "Trial Dates" and "Delivery Dates" during the order creation process, the system can flag orders that are at risk of missing their deadlines.

Digital oversight ensures:

- Reference Images: Masters and tailors can view reference images for special instructions directly within the app, reducing errors that lead to time-consuming re-stitching.

- Automated Updates: Once an order moves to "Ready for Delivery," the app can facilitate a WhatsApp notification to the customer, reducing the time the garment spends sitting on the shelf.

- Balance Tracking: Ensuring the garment is only handed over once the payment status is "Cleared" or "Received."

Conclusion

Reviewing operational efficiency is no longer about micromanagement; it is about having the right data at the right time. By implementing a tailoring app like GrowStitch, boutique owners can transform a chaotic workshop into a streamlined production line. From spotting bottlenecks to customizing workflows, these digital tools provide the market awareness and internal control necessary to scale a fashion business in a competitive market.

The first 1,000 customers get early-bird access, download the app now and get ahead before everyone else does.

Frequently Asked Questions

1. How does the app help me if I have multiple tailors working on one dress?

The app allows you to assign different production stages to different team members. For example, the cutting can be assigned to the "Master" and the stitching to a specific "Tailor," allowing you to track each person's contribution.

2. Can I use the app if my workshop is in a different location than my storefront?

Yes. Because GrowStitch is a cloud-based tailoring application, you can see real-time updates from the workshop on your phone, regardless of where you are located.

3. What happens if we skip a production stage in real life?

The app is flexible. You can customize your workflow during onboarding to skip stages that don't apply to your boutique, or manually move an order forward if a stage is completed quickly.

4. Does the app track the time taken for alterations?

While the app focuses on the primary production stages, you can manage alterations by tracking the "Order Close" and "Delivery" statuses to ensure the customer is satisfied before the transaction is finalized.

5. How do voice descriptions help in production efficiency?

Voice descriptions allow the salesperson to record specific customer requests (like "keep the neck deep" or "add extra tassels") that might be hard to describe in text. The tailor can listen to these directly, reducing the chance of mistakes and rework.

6. Can I print a summary of the day's production tasks?

Yes. You can generate and download a "Job Sheet" that contains all the necessary order details, which can be printed or shared via WhatsApp with your production team.