How does a tailor app improve accuracy?

A tailor app revolutionizes production by converting static measurements into dynamic, actionable data for every stage of the stitching process. Instead of relying on handwritten notes that can be misread or lost, a digital tailor app measurement system ensures that every inch recorded is accurately transmitted to the cutting and stitching teams. This digital transition minimizes human error, standardizes workflows, and provides real-time visibility into the status of every garment, from the initial cut to the final finishing touch.

Transforming Measurements into Production Data with GrowStitch

In a traditional setup, measurements are often just numbers on a page, disconnected from the actual production workflow. GrowStitch changes this by treating tailor app measurement data as the blueprint for the entire manufacturing process.

When a measurement is entered into GrowStitch, it doesn't just sit in a customer's file; it becomes part of a structured production pipeline. This ensures:

- Standardization: Every tailor and master cutter interprets the data in the same way, reducing the "interpretation errors" common with handwriting.

- Accessibility: Production teams can access the exact specifications they need without having to chase down the original order book.

- Integration: The measurements are directly linked to the specific garment type (e.g., blouse, kurta, suit), ensuring that the production team knows exactly which template to follow.

By digitizing this initial step, the tailor app lays the foundation for a smoother, more predictable production cycle.

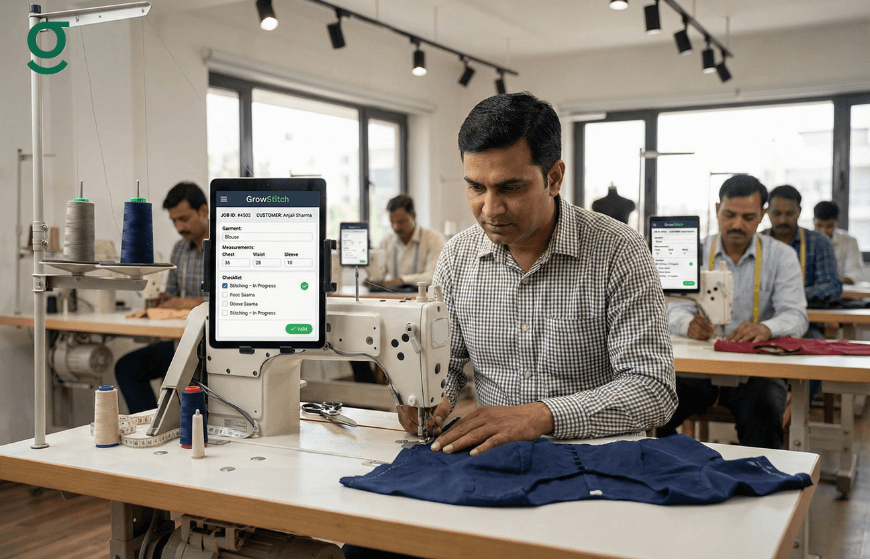

Using GrowStitch Job Sheets for Error-Free Stitching

One of the most critical tools for quality control in a tailoring unit is the Job Sheet. GrowStitch automates the creation of these sheets, ensuring that the instructions given to the tailor are precise and complete.

A GrowStitch Job Sheet includes:

- Detailed Measurements: The exact tailor app measurement data recorded during the consultation.

- Material Specifications: Details on linings, buttons, and embroidery are clearly listed to prevent wastage or substitution errors.

These digital Job Sheets can be downloaded, printed, or shared via WhatsApp, ensuring that the person stitching the garment has every piece of information they need right in front of them. This eliminates the "guesswork" that often leads to alterations and rejected orders.

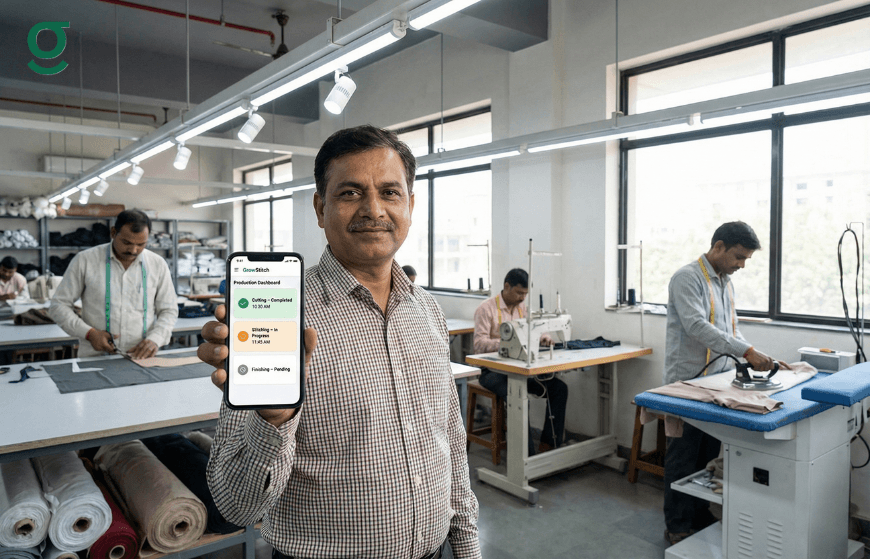

Real-Time Stage Tracking with GrowStitch

Managing a busy workshop requires knowing exactly where every order is at any given moment. GrowStitch's tailor app provides a "Production Insight" feature that breaks down the lifecycle of a garment into tracked stages.

Common production stages include:

- Cutting: The fabric is cut according to the measurements.

- Stitching: The garment is assembled.

- Finishing/Hemming: Final touches are added.

- Quality Check (QC): The garment is inspected against the original tailor app measurement data.

Admins can customize these stages during onboarding to match their specific workflow. By tracking these stages in real-time, boutique owners can answer customer status queries instantly without having to physically check the production floor.

Identifying Bottlenecks with GrowStitch Production Insights

Efficiency isn't just about speed; it's about flow. GrowStitch helps owners identify where orders are getting stuck. The tailor app aggregates data to show how long orders remain in each stage.

If the data shows that orders are consistently delayed at the "Finishing" stage, an owner can investigate whether they need more staff or if the current team is facing equipment issues. This level of insight allows for data-driven decisions rather than gut-feeling adjustments. It transforms the boutique from a reactive business (fixing problems as they happen) to a proactive one (preventing problems before they start).

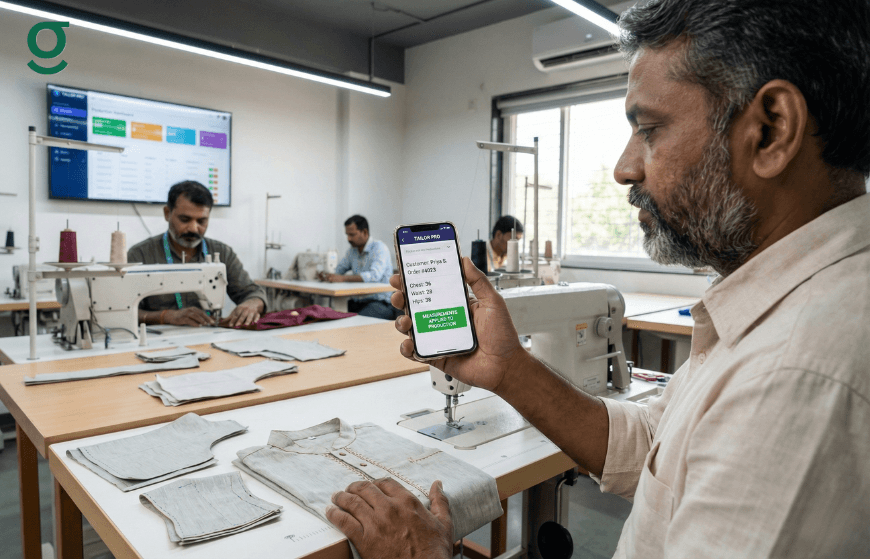

Improving Delivery Speed with Digital Workflows

Ultimately, the goal of using a tailor app is to get the finished product to the customer faster and more accurately. Digital workflows streamline the handoffs between different departments.

- Instant Handovers: Once the cutting is marked as complete in the app, the stitching team knows the work is ready for them. There is no downtime waiting for physical files to be moved.

- Automated Reminders: The system can flag orders that are approaching their delivery date, ensuring they are prioritized in the production queue.

- Reduced Rework: By ensuring the correct tailor app measurement and design details are available at every step, the rate of alterations drops significantly. Fewer alterations mean more time spent on new orders, directly increasing the shop's capacity and delivery speed.

Conclusion

Adopting a tailor app like GrowStitch is a strategic move for any boutique aiming to scale. It shifts the business from a chaotic, paper-dependent operation to a streamlined, data-driven enterprise. By effectively utilizing digital tailor app measurement records, Job Sheets, and real-time tracking, owners can ensure error-free stitching, identify production bottlenecks, and deliver quality garments on time, every time.

And if you move now, the first 1,000 users get exclusive early-bird access, download the app today and stay ahead while others struggle to catch up

Frequently Asked Questions

1. Can I customize the production stages in the tailor app?

Yes. GrowStitch allows you to customize, skip, or assign specific production stages (like stitching, hemming, or finishing) during the onboarding process to match your workshop's specific workflow.

2. How does the app help reduce stitching errors?

The app generates detailed Job Sheets that include the exact tailor app measurement data, and reference images. This ensures the tailor has clear, comprehensive instructions, reducing the chance of misinterpretation.

3. Is it possible to track the status of an order from my phone?

Yes. The tailor app provides real-time visibility into every stage of production, allowing you to track orders from cutting to delivery directly from your mobile device.

4. Can I share measurement details with my tailors digitally?

Yes. You can share the Job Sheet, which contains all measurement and design details, directly via WhatsApp or print it out for the shop floor

5. How does the app handle rush orders or express delivery?

You can mark orders for express delivery within the app. This, combined with real-time tracking, helps you prioritize these orders in the production queue to meet tighter deadlines.